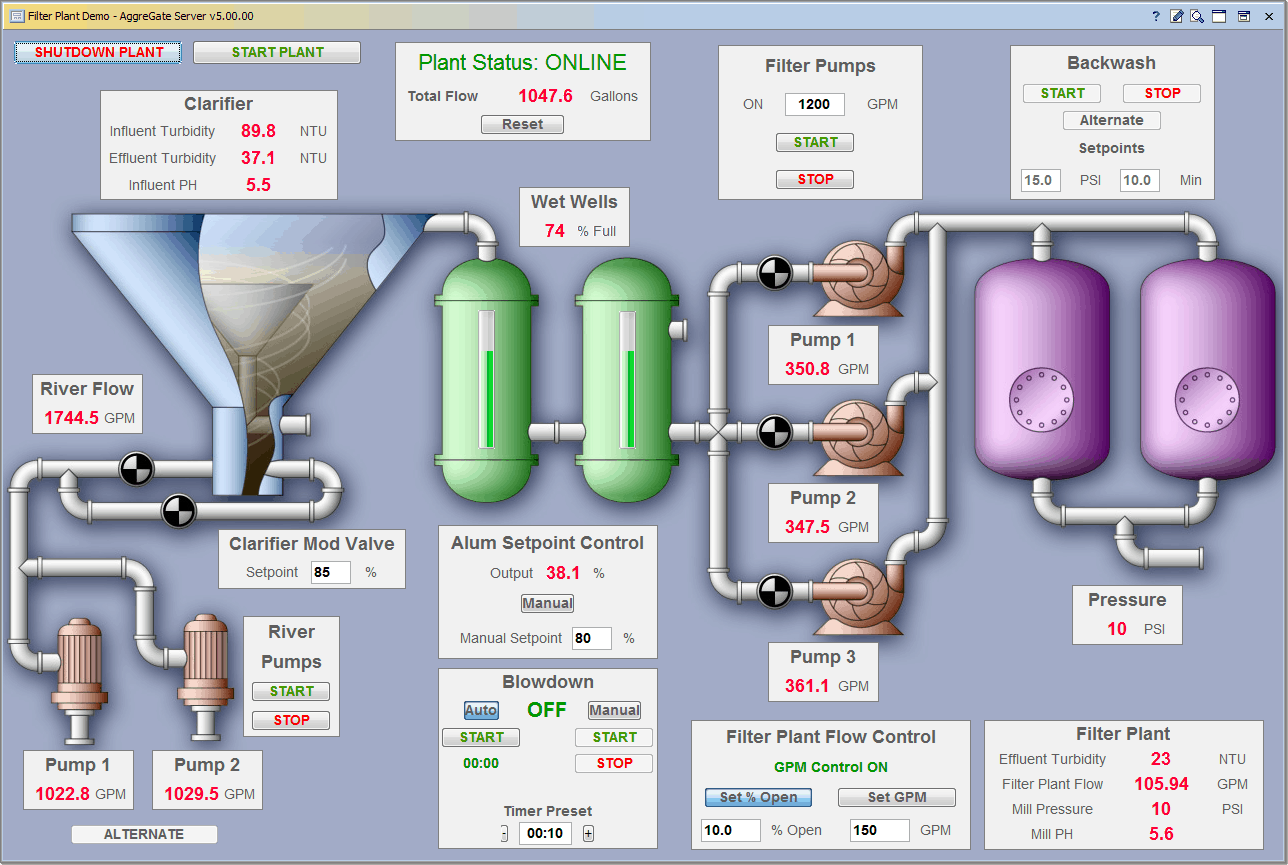

SCADA is a control system architecture comprising computers, networked data communication and graphical user interfaces for high level process supervisory management, while also comprising other devices like PLC's and PID controllers to interface with process plant or machinery.

SCADA systems are crucial for industrial organizations since they help to maintain efficiency, process data for smarter decisions, and communicate system issues to help mitigate downtime.

SCADA systems are also used in companies in the public and private sectors to control and maintain efficiency, distribute data for smarter decisions, and communicate system issues to help mitigate downtime. SCADA systems work well in many different types of enterprises because they can range from simple configurations to large, complex installations. SCADA systems are the backbone of many modern industries, including:

|

|

|

Virtually anywhere you look in today’s world, there is some type of SCADA system running behind the scenes: maintaining the refrigeration systems at the local supermarket, ensuring production and safety at a refinery, achieving quality standards at a waste water treatment plant, or even tracking your energy use at home, to give a few examples.

Effective SCADA systems can result in significant savings of time and money. Numerous case studies have been published highlighting the benefits and savings of using a modern SCADA software solution such as Ignition.